The 6-Second Trick For Copper Foil

Wiki Article

The Definitive Guide to Copper Foil

Table of ContentsThe Greatest Guide To Copper Foil8 Simple Techniques For Copper Foil8 Easy Facts About Copper Foil DescribedThe Best Guide To Copper FoilFacts About Copper Foil RevealedHow Copper Foil can Save You Time, Stress, and Money.

This technique can be used on any product that can hold up against the warmth of the welding torch-- as much as 1000 levels Fahrenheit. Add a ring, loophole or various other searching for in the soldering procedure and the glass is transformed into an element that can be utilized as an appeal, necklace or web link.Make an impact, remove the foil then cut at the perception. ACTION 2 STEP 3 Neatly press the aluminum foil versus the slide. Utilizing a burnisher, smooth the foil so it is pushed safely onto the slide in addition to smooth. STEP 4 Grasp the slide with tweezers kept in a third hand so you can work hands-free.

Solder will not remain on the foil if it isn't fluxed effectively. STEP 5 While servicing a heatproof surface area, using a blowpipe or collaborating with the soldering suggestion in position on the soldering lantern, spark the torch and also allow the pointer to warm up. Press the idea to the solder so a little bit of solder is gathered.

The Definitive Guide to Copper Foil

ACTION 7 Allow the setting up to cool down, then clean it with cozy water and soap prior to utilizing in a layout. "Exceptional article on tinning copper foil!" - Beck! "I just intend to thank for all the various concepts Fire Hill shares with us, your consumers, so that we can try different techniques.Numerous many thanks. Genuinely," - Nora Have an inquiry concerning this project? Permission to duplicate this instruction sheet is granted for non-commercial instructional purposes only.

9 Easy Facts About Copper Foil Shown

In an electrodeposited copper production process, the copper foil is transferred on a titanium rotating drum from a copper solution where it is attached to a DC voltage source. The cathode is connected to the drum and also the anode is immersed in the copper electrolyte solution. When an electric area is used, copper is transferred on the drum as it turns at a really slow speed.The slower the drum rate, the thicker the copper gets and the other way around. The copper is attracted as well as accumulated on the cathode surface of the titanium drum. The matte and also drum side of the copper aluminum foil go with different treatment cycles to ensure that the copper might be ideal for PCB manufacture.

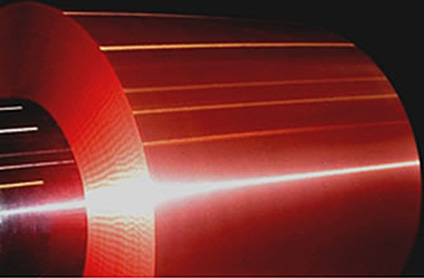

The procedure is regulated as though the product just gets longer and does not change its width. As the sheets can not be formed any kind of better in this state (the product has job set extensively) they undergo a warmth treatment and are warmed to about 550C. Number 2: Rolling of copper foils Number 3: Copper foil items.

Indicators on Copper Foil You Need To Know

Receive the most recent information on new promotions, special deals, and also new arrivals.

- The main function for aluminum foil made use of in stained glass work is simply to fold up over the edge of the glass to enable the sides to be soldered with each other. Typically, routine copper aluminum foil is used, nonetheless, simple copper foil can create a problem if it is used on glass that is relatively clear - the within side of the aluminum foil can be seen try this via the glass and also it will cause a "copper halo" along the seam.

If you prepare to leave the solder joints silver tinted, usage silver backed aluminum foil. If you prepare to make use of black aging on the solder joints, make use of black backed aluminum foil. - Copper aluminum foil is usually made use of as an edging material on glass ornaments, bevels as well as for other craft jobs. If the glass is fairly clear, the exact same "halo" trouble noted above will occur.

8 Easy Facts About Copper Foil Described

Silver Both Sides Aluminum foil permits you to have a silver front side to a craft job without the need to solder the aluminum foil. It has a sticky backing like the copper aluminum foil foils.Lots of Slice devices appropriate for reducing copper aluminum foil - copper foil. You can decide which one is best based upon your application, the amount of room you have to function in, whether you're making straight or curved cuts, as well as the quantity of precision called for. If your copper foil has a sticky support, the amount of stress you use will figure out whether you punctured the simply the foil layer, or both the foil and also its backing.

This special material isn't tough to function with, if you have the right tools. Slice makes a variety of blades and also cutters that work well. Several of these knives have interchangeable blades, permitting you to tailor the blade to your details cutting task. Our click for source scissors additionally function well for many applications.

The smart Trick of Copper Foil That Nobody is Talking About

Copper aluminum foil is currently made use of for a vast array of applications in the electro-engineering market owing to its outstanding conformability, high electrical conductivity, and also securing abilities. Copper foil can be soldered, that makes it excellent for basic grounding applications. Double-sided tin-clad copper is utilized where optimal resistance to the external setting is required.

Report this wiki page